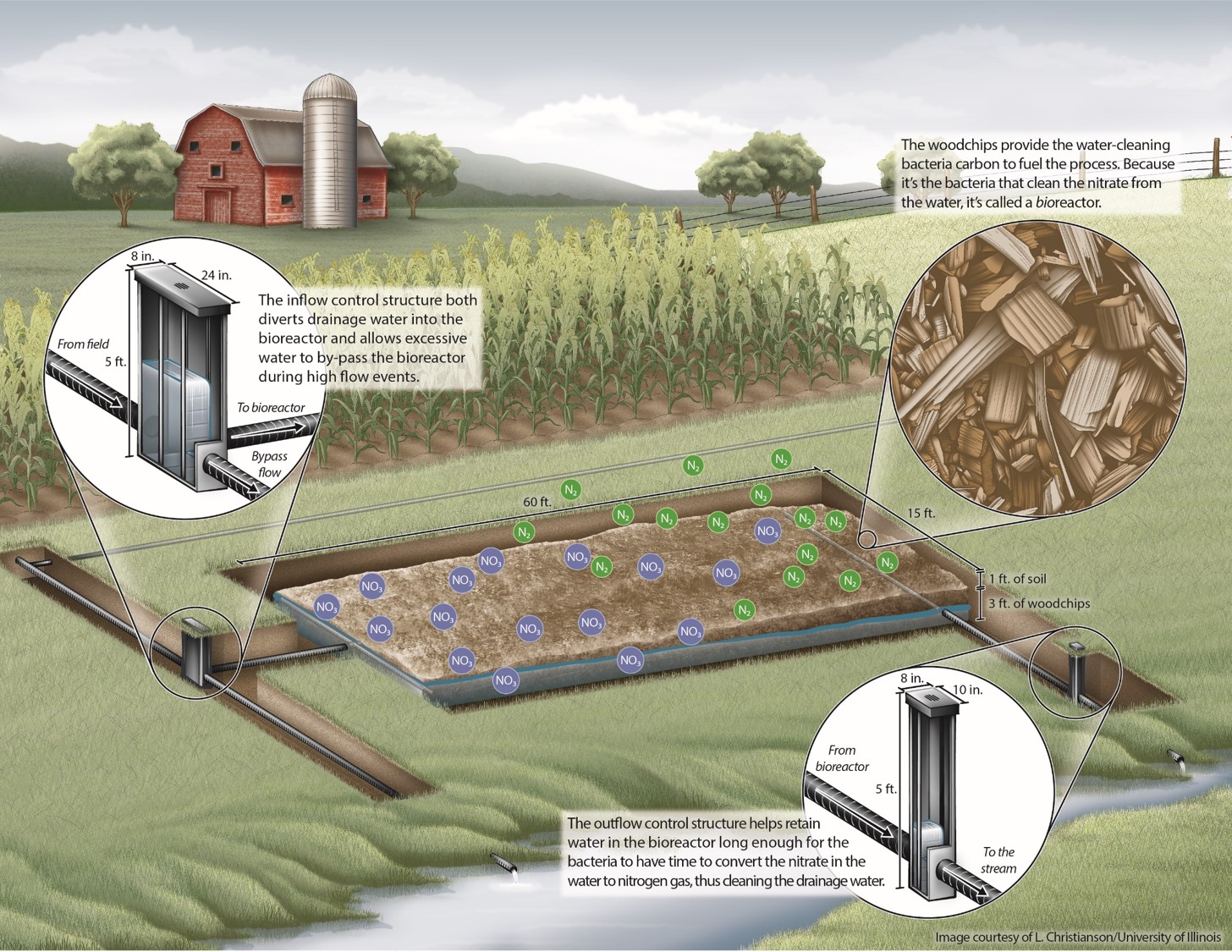

Denitrifying woodchip bioreactors remove nitrate from subsurface (“tile”) drainage water without significantly impacting production ground or crop yield. Inside a bioreactor, provision of a solid organic carbon source in addition to maintenance of anoxic conditions allows the natural process of denitrification to be enhanced, meaning waters leaving these treatment systems have reduced nitrate loads.

Access a 2-page bioreactor factsheet here.

Bioreactors for Illinois: Smaller, Better, Faster

Considering the scale of new water quality goals, there is an increasing need to design bioreactors to remove nitrate more effectively under both high and low flow rates, from cool early-season drainage, and with a smaller bioreactor footprint. The goal of this work is to test novel full-size bioreactor designs intended to maximize nitrogen removal while limiting land removed from production. Four novel bioreactors will be designed, built, and monitored: two for treatment of ditch drainage (“Ditch Bioreactors”), one will include a step-feeding system for high flows (“High-Flow Booster Bioreactor”), and one will take advantage of solar heating to better treat low temperature drainage water (“Heat-enhanced Bioreactor”).

Funding Partner: Illinois Nutrient Research & Education Council

Co-PI: Dr. Richard Cooke, Biological & Agricultural Engineering, University of Illinois (Dr. L. Christianson, Lead PI)

Evaluation of bioreactor performance and practical concerns in Illinois and across the Midwest

Evaluation of bioreactor performance and practical concerns in Illinois and across the Midwest

The Illinois Nutrient Loss Reduction Strategy assigns denitrifying woodchip bioreactors a 25% nitrogen (N) loss reduction for tile drainage. To further establish this value, bioreactors designed to USDA NRCS standards must be monitored to determine their long-term N removal performance. Such data for “normal” bioreactors is required to ensure the N loss reduction values used for bioreactors across the Midwest are the most science-based and up-to-date. We are currently studying woodchip bioreactor performance at a variety of private farms around the state to monitor N removal in addition to many other parameters.

Funding Partner: We’re so pleased to have a variety of partners in this work: the Illinois Farm Bureau, the Illinois Land Improvement Contractors Association, the Illinois NRCS, and many others.

Lead PI: Dr. L. Christianson

International Woodchip Bioreactor Collaborations

We collaborate with a variety of scientists, engineers, and farmers around the world to trial bioreactors in new areas and for new types of waters and wastewaters. From agricultural ditches in Europe to fish farms and small municipalities across North America, we are working towards refining this simple water treatment technology.

We collaborate with a variety of scientists, engineers, and farmers around the world to trial bioreactors in new areas and for new types of waters and wastewaters. From agricultural ditches in Europe to fish farms and small municipalities across North America, we are working towards refining this simple water treatment technology.

Funding Partner: Various

Lead PI: Dr. L. Christianson